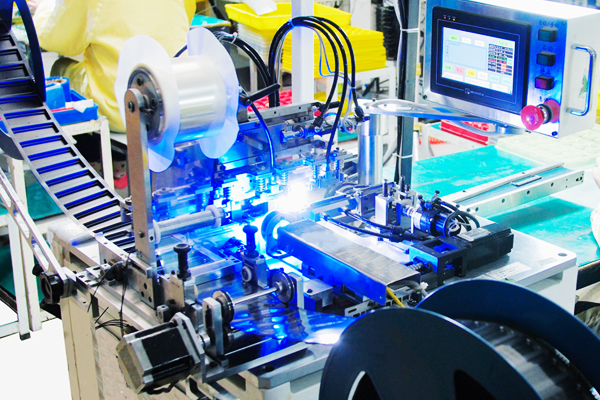

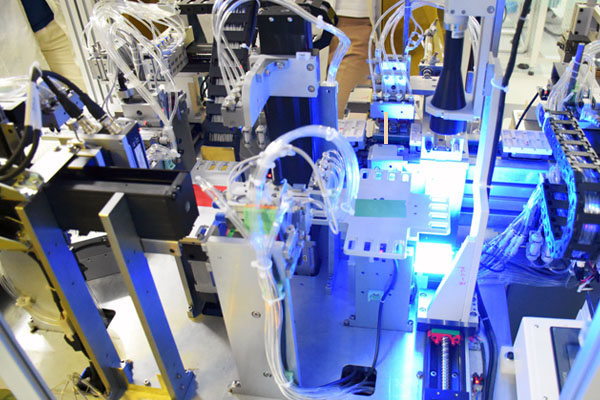

Automation & Assembly

A highly innovative corporate environment, coupled with close cooperation with technical schools, has achieved CONCRAFT's independent development capabilities for automation equipment, providing a steady stream of power for efficient production. Through highly automated production and process integration, we create the highest value for customers with the most economical and time-efficient solutions!

Automation and process integration services:

Improve production efficiency, yield and capacity

Reduce labor and reduce costs

Short lead time and ensure the consistency of production

Reduce waste/scrap

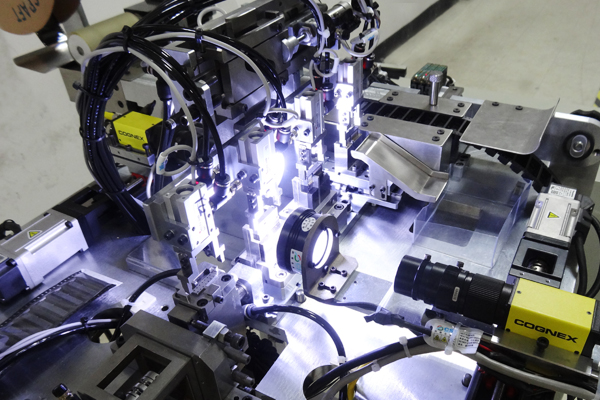

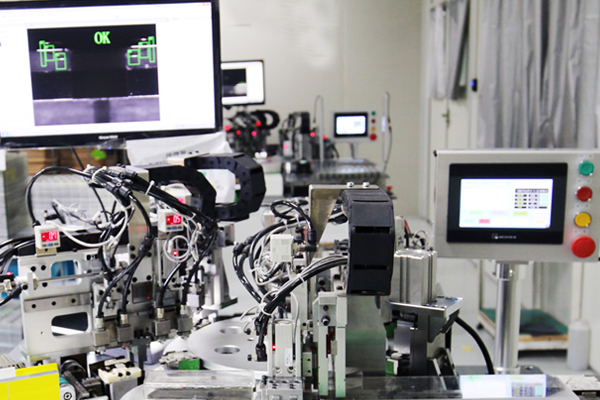

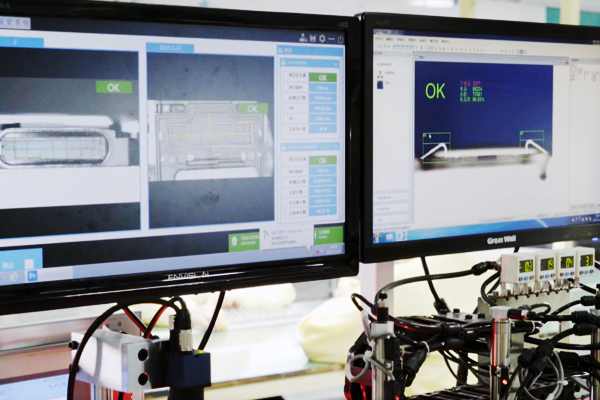

Online quality inspection

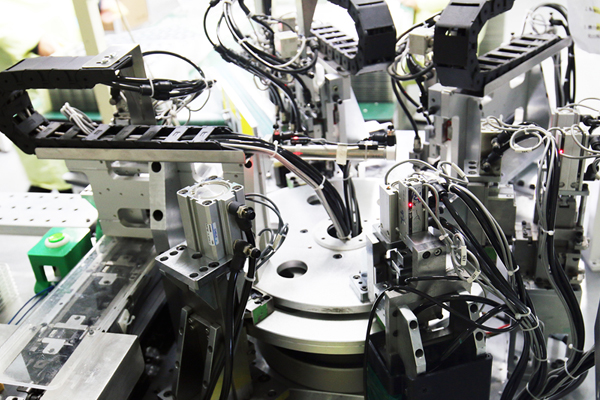

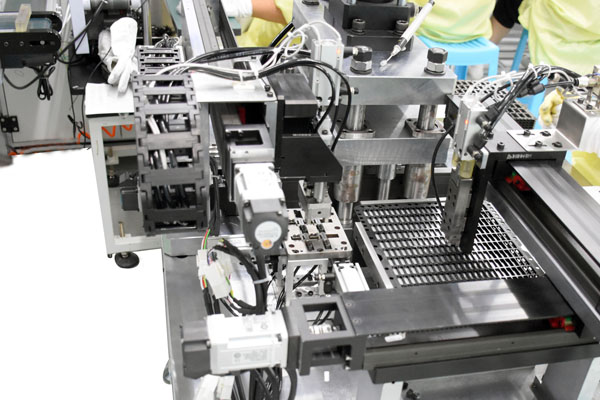

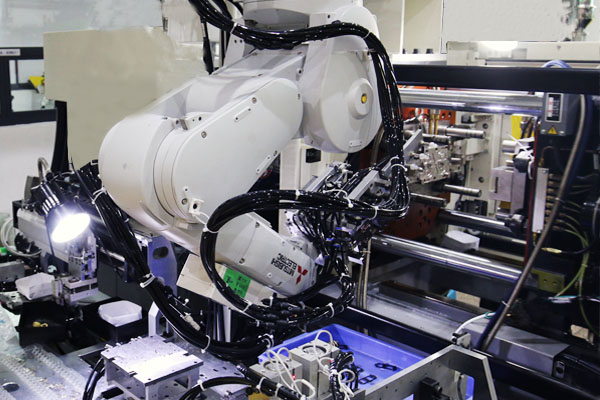

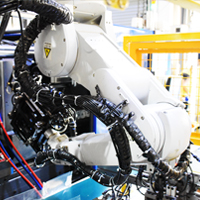

Manipulator pick and place

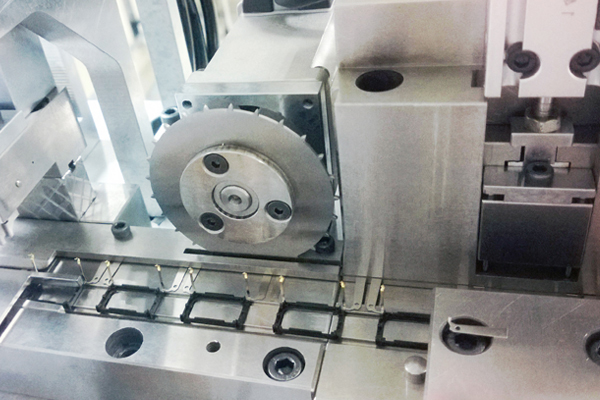

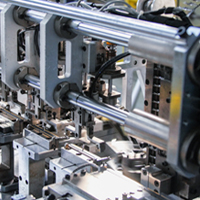

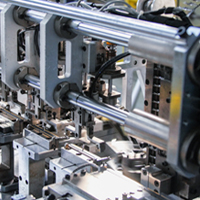

Automatic metal bending machine

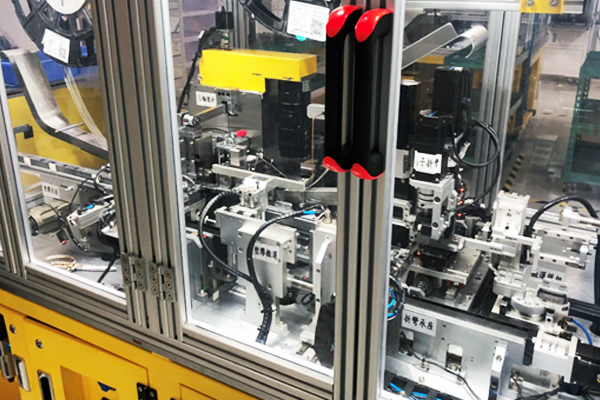

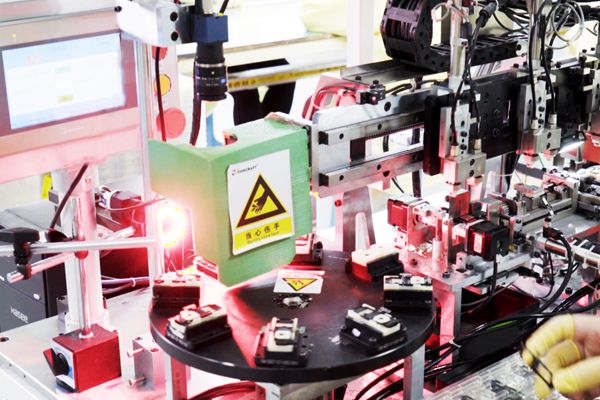

Automatic assembly of precision parts

Automatic packaging system

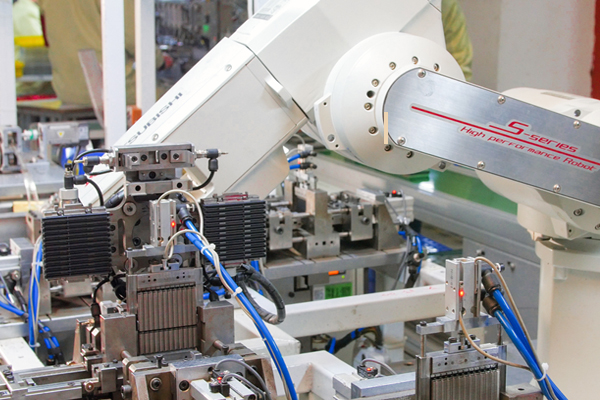

Development, optimization and integration of fully automated systems

Design and manufacture of semi-automatic machines

The self-made rate of automated machinery is 100%.

Under the global industry 4.0 environment from manufacturing to production, Kangerfu has always been at the forefront of the times, with automated production lines innovating, continuously improving product quality, improving production efficiency and stability,

creating brand new for customers value.

Automation application

Soldering (Laser)

Stiffener Plant-In

6-Axis Robot Operation

Ejection and Laser Coding

Curing/ HC

Tool Cooling

Clamping and Injection

Automation / Auto-Align-Soldering

Versatile Insert Molding

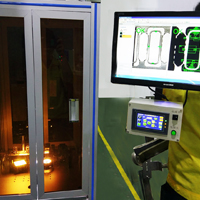

Automatic CCD inspection and packaging

Item Location (equipped on Robot)

Mesh Quality Inspecti

Dimension Inspection

Cosmetic Inspection

Dimension + Cosmetic Inspection

In Total, around 300 sets