Rapid prototyping

Rapid prototyping enables us to test the design and functionality of the parts before investing in full production. Our team develops prototypes quickly through soft tool.

>>Design better and faster:

>>bring your drawing to product within 7 days For small quantity trial-run imple or complex geometrics

Rapid prototyping of plastic parts as an example:

Take the plastic injection molded parts’ prototyping as an example:

The first step is to review the client’s design and prints, along with evaluating their material specifications for the designed part.

We build a prototype mold and employ simulation software to evaluate how the material and the part will function in the mold.

If the simulation reveals weak spots, the mold can be redesigned to improve manufacturability.

After that, the client is informed via online conferences where test results can be reviewed to determine if changes are necessary before full production. Through this efficient communication , our engineering team will decide a final product design to try on the soft tool proposal with the customer in a limited time.

Besides, based on the soft tool we have the following methods to reduce the cycle time:

At last, the success of any project is determined by the strength of the project team. Each project is allocated with a PM, who is responsible for coordinating different departments, monitoring each process and dealing with emergencies so as to ensure the prototyping is carried out smoothly.

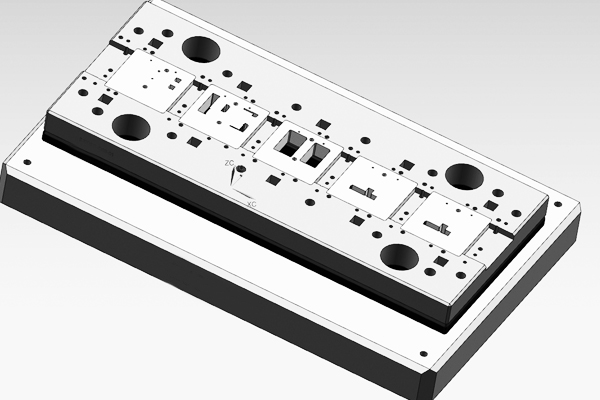

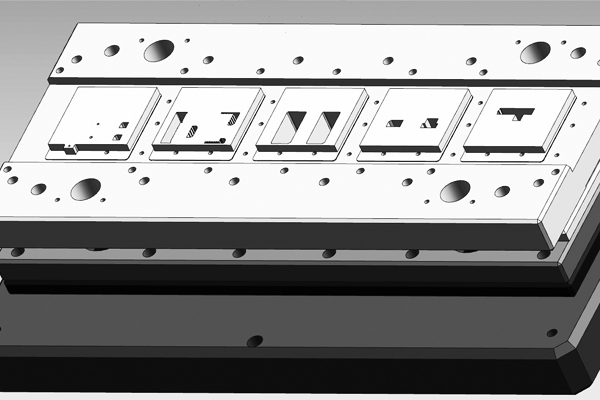

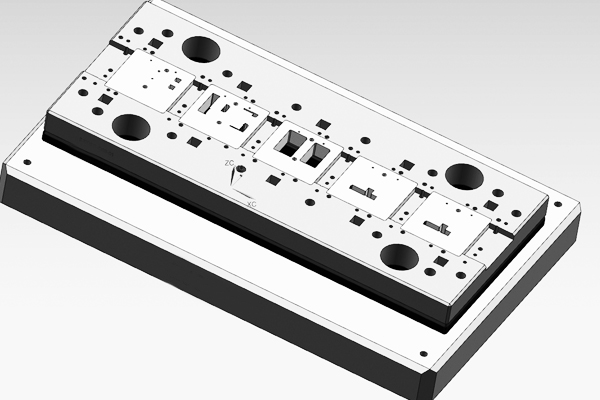

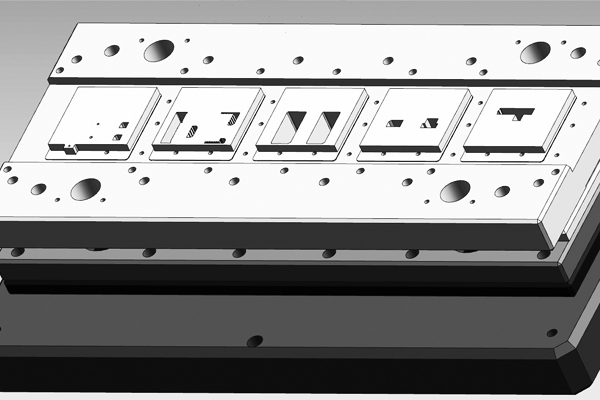

Stamping soft mold

Stamping soft mold

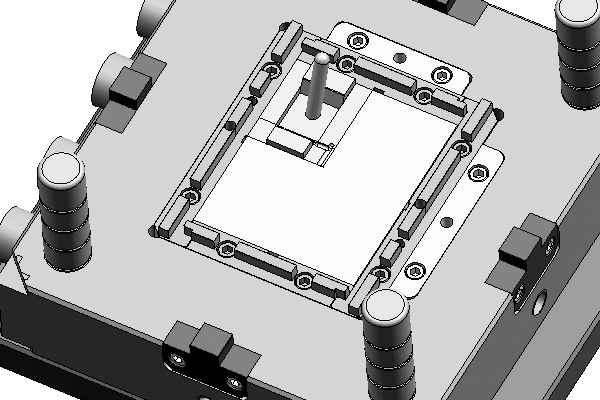

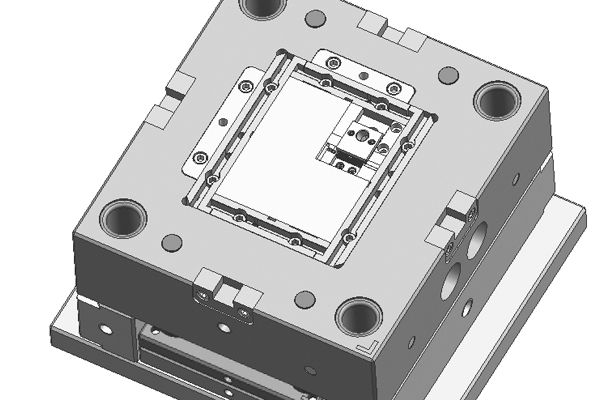

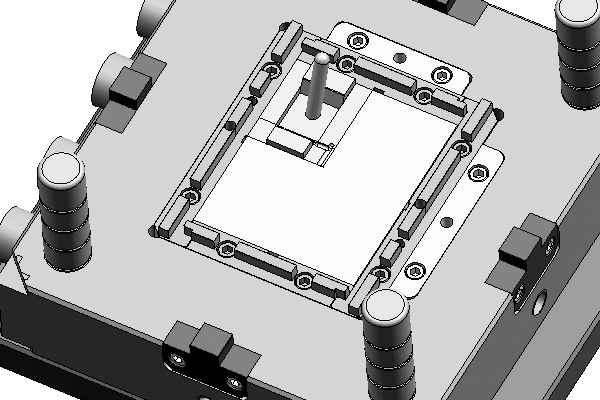

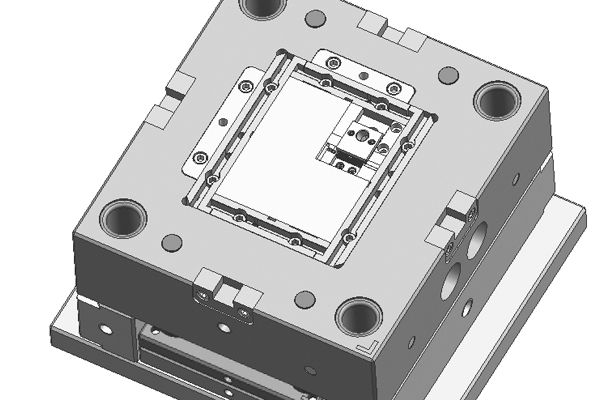

Injection soft mold

Injection soft mold