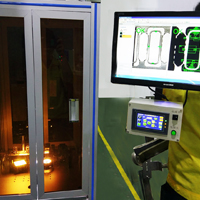

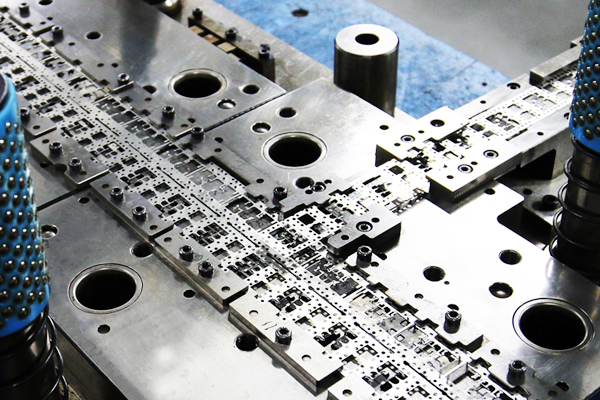

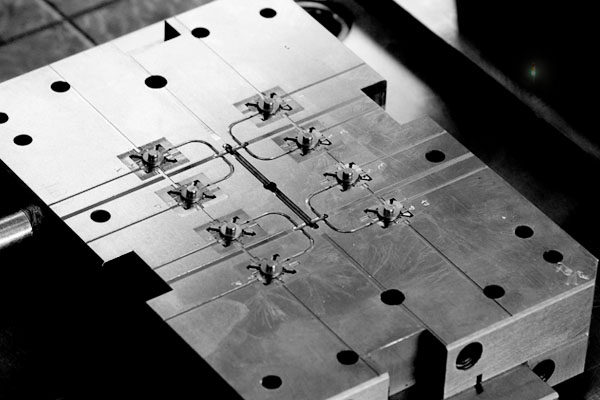

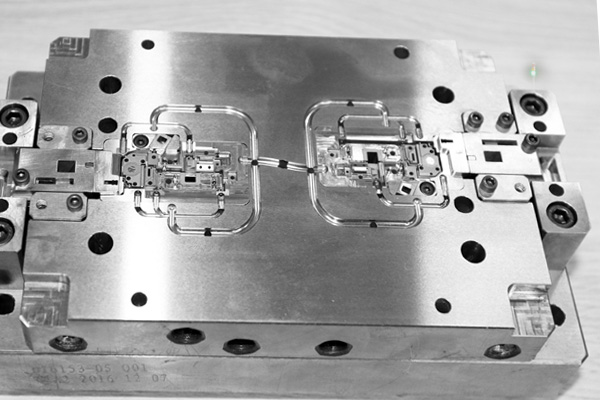

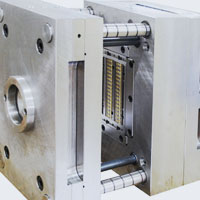

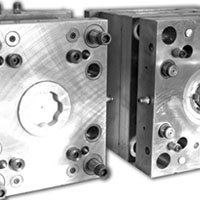

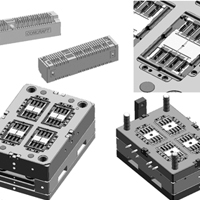

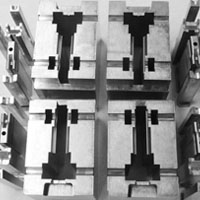

CONCRAFT's mold design and manufacturing capabilities can not only meet the needs of the company, but also provide customers with the needs of each station in mold processing, from product design, mold design, and selection of the best materials to mold production and maintenance.

特殊公差可以控制在0.001mm左右,搭配先進的3R以及EROWA夾具系統,再加上量身定制的製造管理系統,並配合專業先進的分析軟體

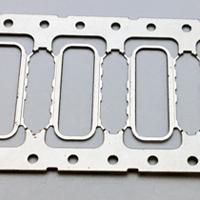

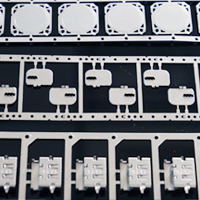

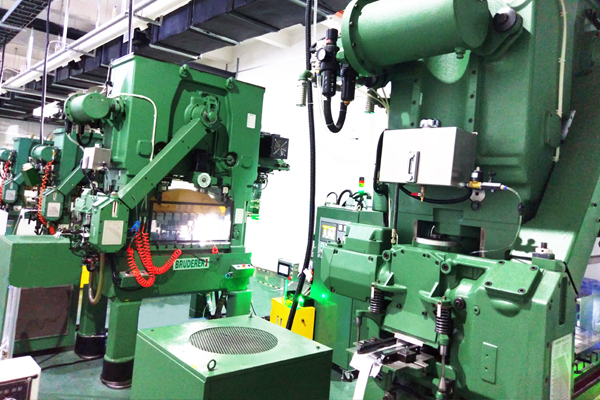

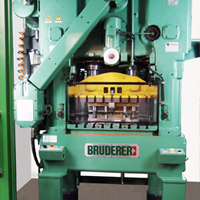

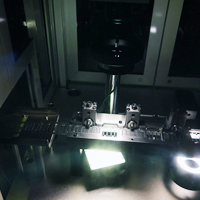

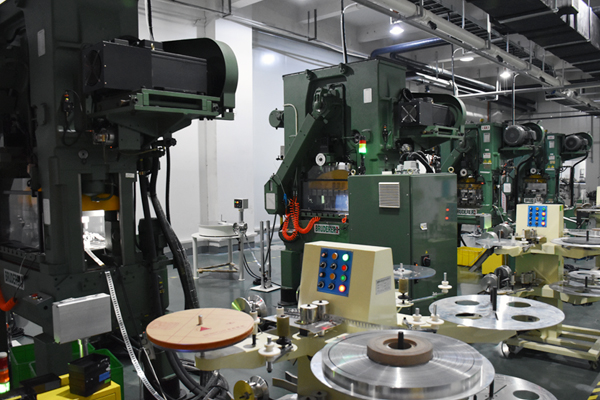

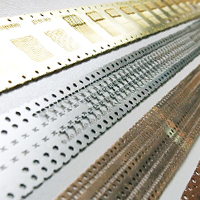

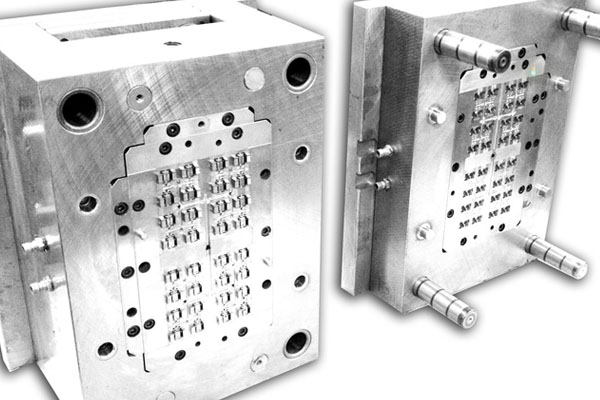

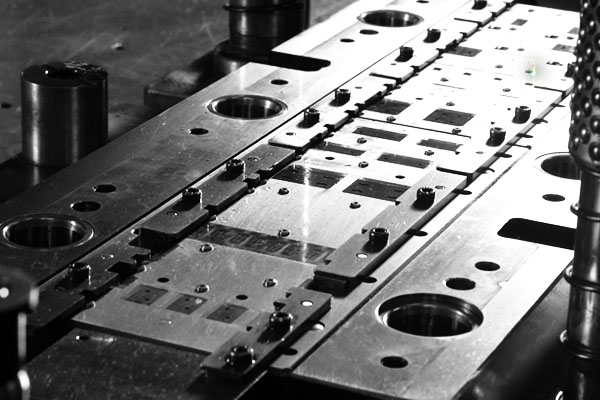

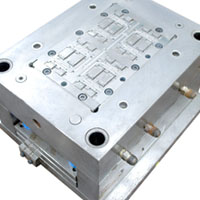

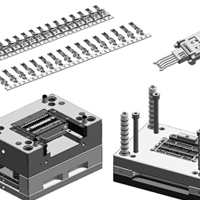

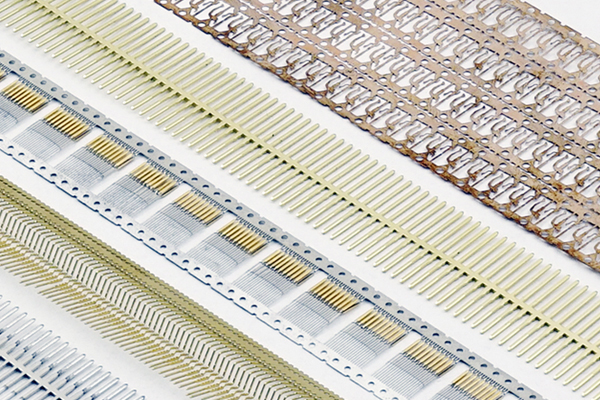

With the high-speed precision stamping machines, and sophisticated stamping die design, we have the ability to handle all kinds of metal materials’ stamping, forming and forging with high efficiency.

Kangerfu integrates stamping technology to reduce costs for the subsequent injection molding and automated assembly processes, and help customers create maximum profits.

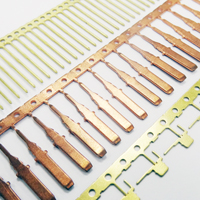

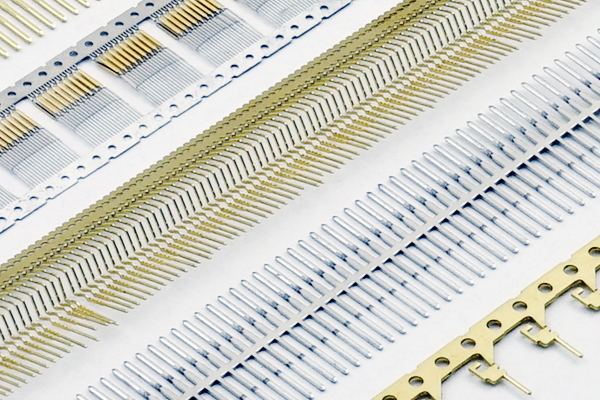

Material: Materials Available / Stainless Steel/Iron / Low/High Carbon Steels /Brass / Phosphorous Bronze / Beryllium Copper / Copper /Copper-Nickel-Zinc Alloy /Coated Materials

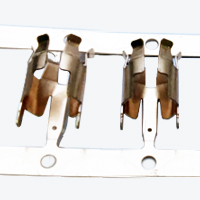

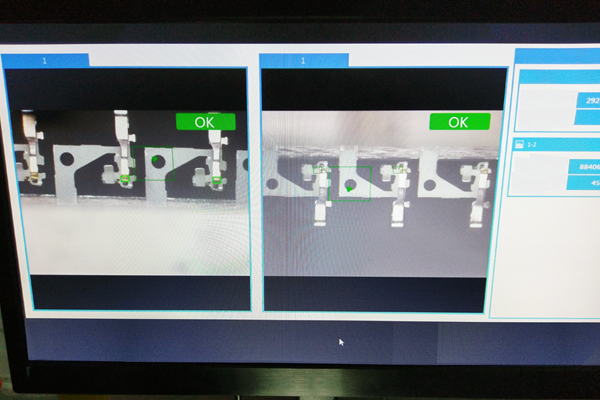

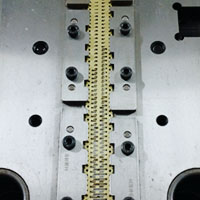

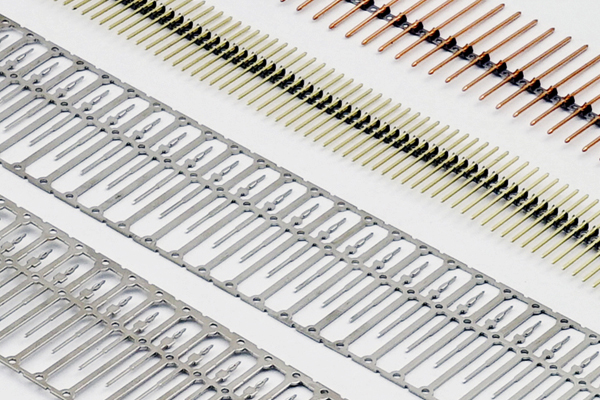

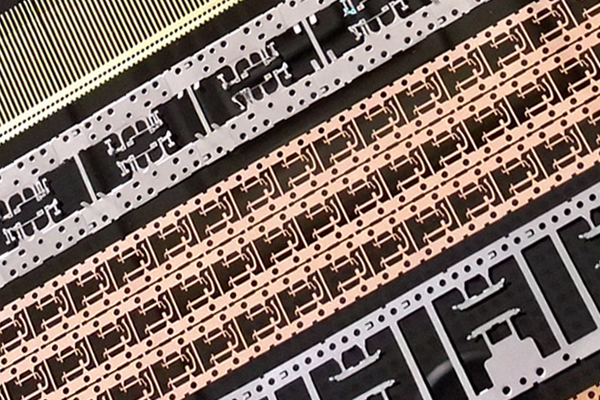

Press- fit terminals

魚眼外形全包圍倒角

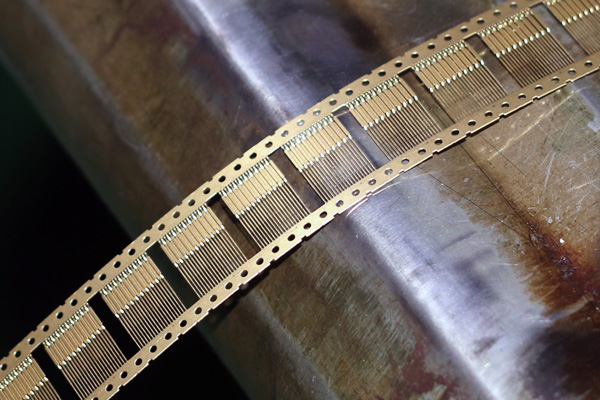

Wire-Pins

接線針

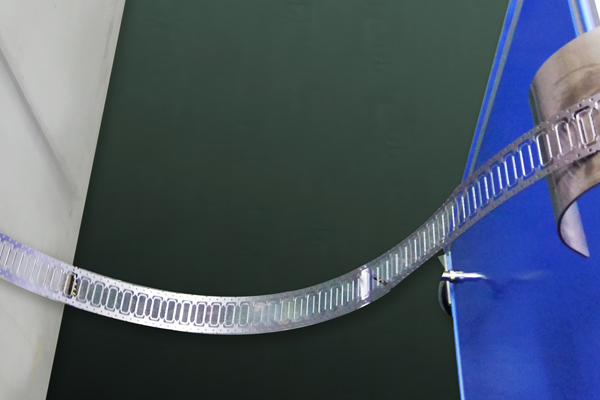

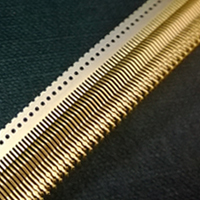

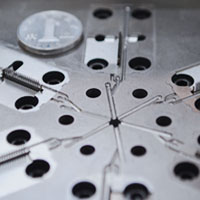

Scrap-less Cutting

無廢料切割

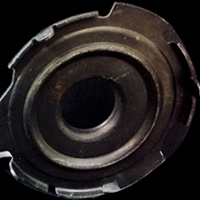

Cross Riveting

十字鉚接