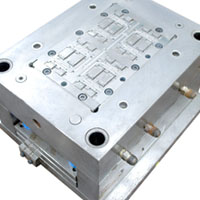

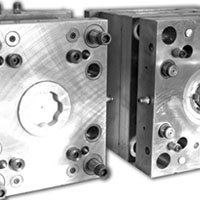

CONCRAFT is one of the few precision metal stamping and plastic injection molding manufacturers that can offer all four of these attributes: Quality, Delivery, Price, and

Capacity. The combination of state-of-the- art equipment, the latest technology, control of all in-house processes , experienced specialists and dedicated workers ensures

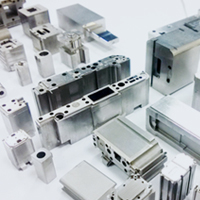

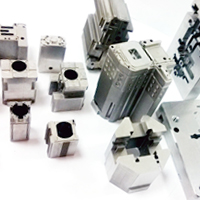

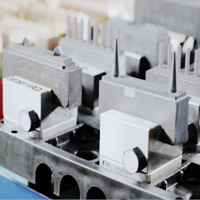

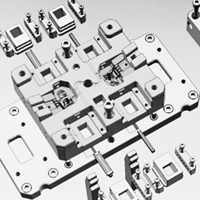

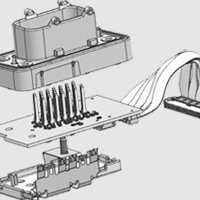

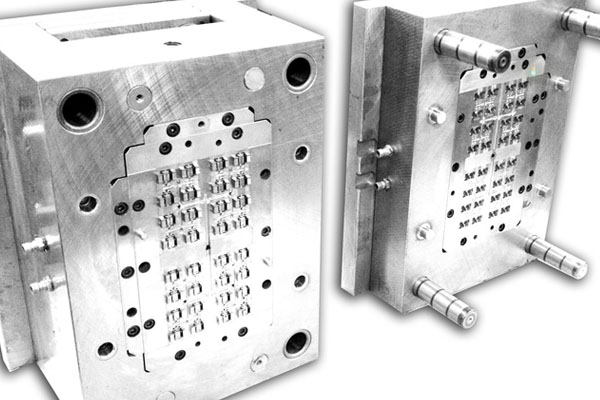

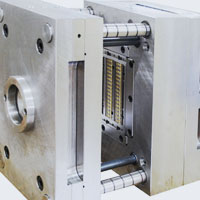

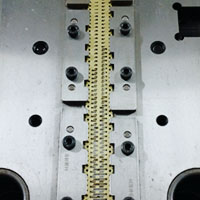

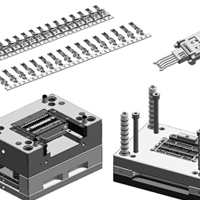

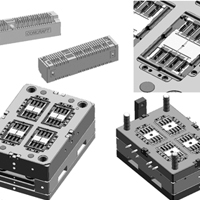

that we could meet customers’ delivery schedules with the highest quality products at competitive pricing. We offer one-stop solution from design to production of all stamped

and molded parts.

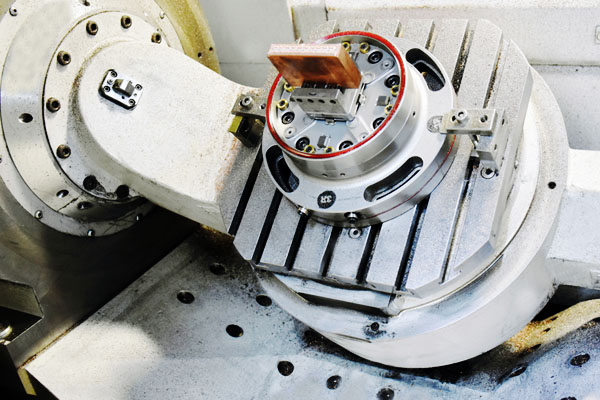

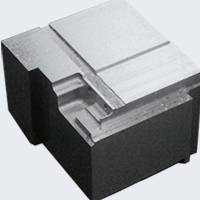

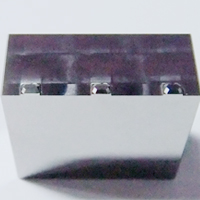

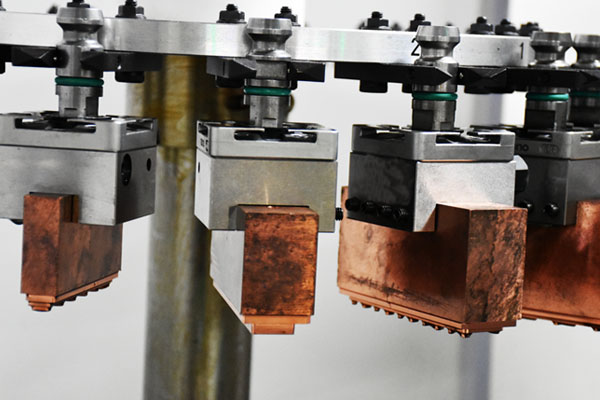

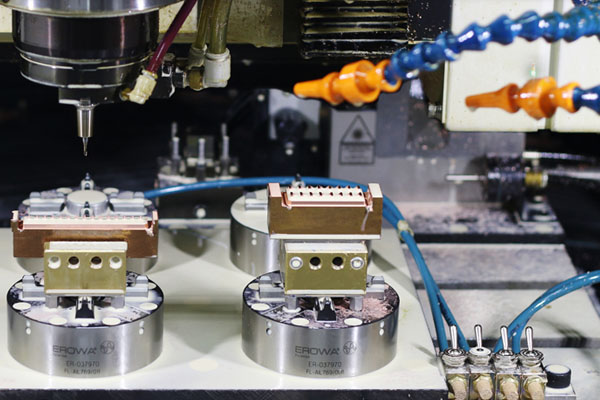

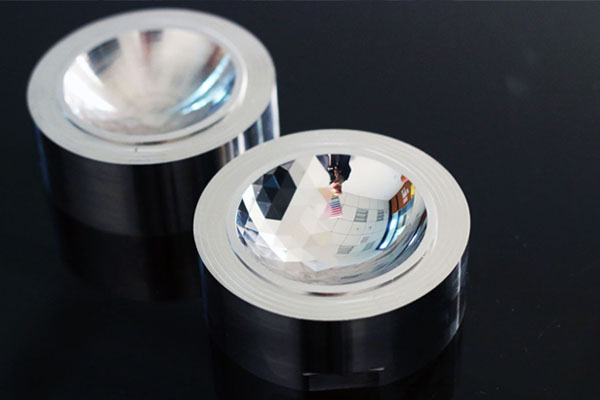

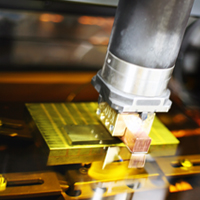

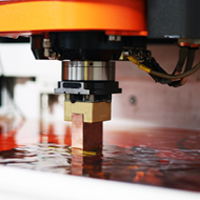

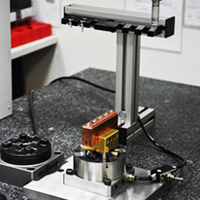

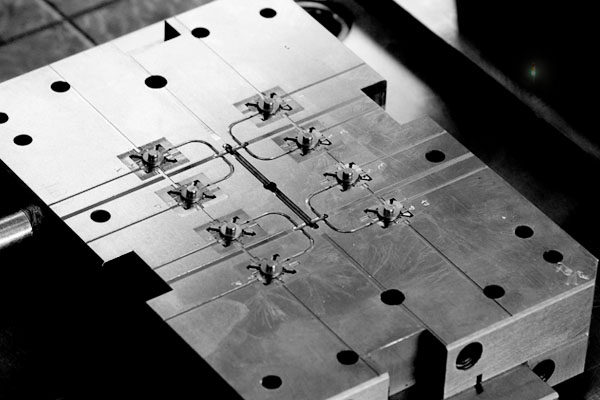

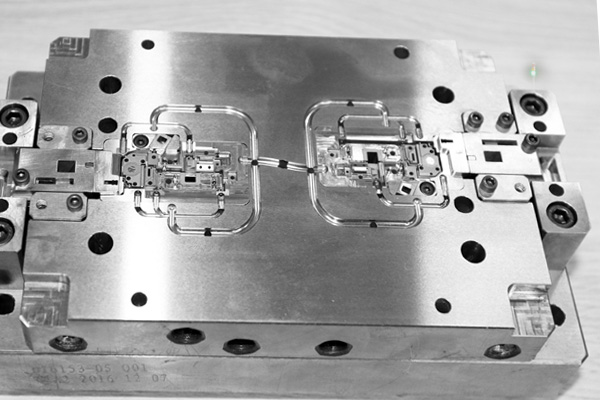

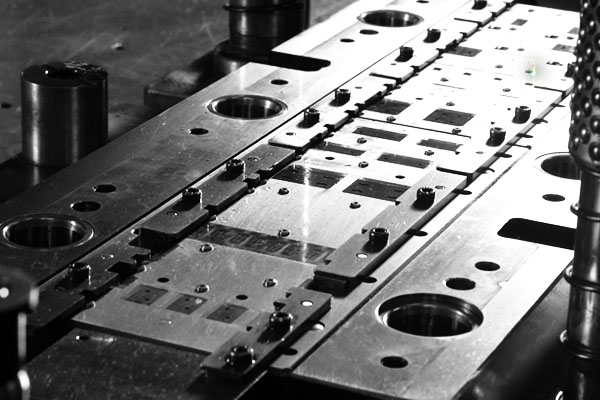

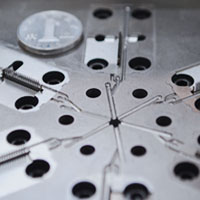

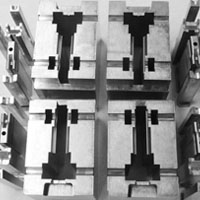

Optimised the advanced 3R/EROWA fixture system with the best equipments, particular tolerance can be controlled around 0.001mm. A tailored manufacturing management system

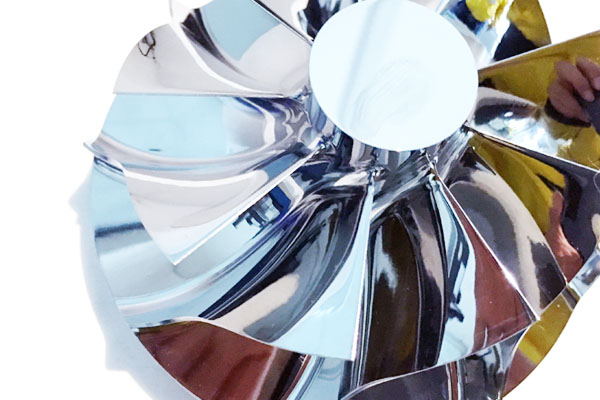

CONCRAFT's precision processing equipment has full capacity, which can provide customers with flexible size requirements and meet customer precision requirements